The Rewatec ASP, formerly referred to as the Conder ASP, is a compact sewage treatment system intended for household use.

It boasts a sturdy and long-lasting construction, as well as low installation and maintenance expenses. This sewage treatment plant is also suitable for smaller commercial ventures.

It is made of polyethylene, takes up very little space, and can accommodate properties with up to 25 occupants.

With over 6,000 successful installations already in the UK, the ASP is a noteworthy product that deserves a dedicated page on our website and a brief overview.

ASP stands for Activated Sludge Process, doesn’t sound very nice, does it? The easiest way to explain this is to describe how the system works;

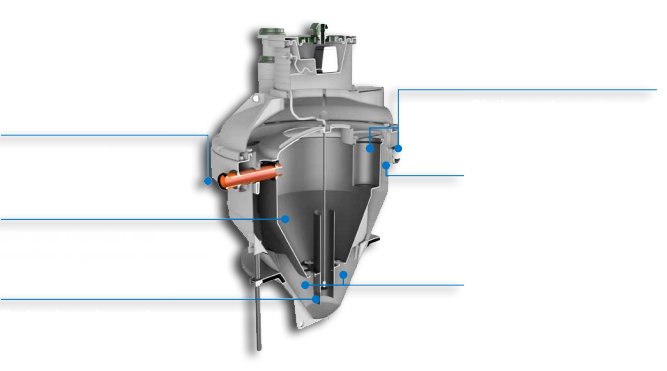

The wastewater enters the tank and settles in the central biozone compartment, where it is aerated using a central diffuser.

A course bubble diffuser, located in a draft tube, introduces oxygen to the bacteria, which then treats the wastewater.

The treated water flows into the outer settlement zone, where settled solids are redirected to the draft tube and returned to the biozone for further treatment.

The final treated effluent exits the Rewatec ASP through a weir located at the outlet level that surrounds the tank's circumference.

The movement and discharge of water within the ASP are accomplished via gravity displacement. However, if the final effluent cannot gravitate to the discharge location, an integral pump is available for such situations.

Annual servicing is a must if you want your system to get operating as the manufacturer designed it, it will also help to prevent costly breakdowns and avoidable repairs. you will often find your warranty is invalidated if you don’t keep up with regular/recommended maintenance schedules.

There is quite a bit to this and often the designers have a handy guide to what must be included in an annual service, you will find this in your owners manual but here is an example of a guide for the Rewatec ASP;

These, and any other requirements, should only be undertaken by suitably qualified engineers (like ours!). Due to electrical, mechanical, risk of falling and serious health dangers, we do not recommend attempting any servicing or repairs yourself.

The frequency of maintenance and servicing required for your system depends on a range of factors, such as its size, design, and age. Some systems may only need to be serviced annually, while others may require more frequent attention.

Did you know that the Environment Agency (EA) recommends that homeowners with a sewage treatment plant, pump station or septic tank arrange regular maintenance and servicing visits? This is super important as it ensures that your tank is working properly and that you comply with environmental legislation.

We know that having an unexpected visit from the EA can be stressful, but regular servicing of your sewage system can minimise the risk of your system failing their tests. Plus, the EA performs random discharge testing, so it's always best to stay on top of your maintenance to avoid any surprises.

If you ever do fail the tests, the first thing the EA will ask is if you have had your sewage system serviced. So why not schedule a regular maintenance visit to keep your system in tip-top shape and stay ahead of any issues?

The key steps in a service of a Rewatec system will depend on the specific type of system and its components, but here are some general steps that may be involved:

Our service technician will begin by inspecting the system to identify any signs of damage, wear and tear, or other issues.

If required the next step is to pump out any accumulated solids or sludge from the system. This is important to prevent clogs or backups and maintain the system's effectiveness.

Once the solids and sludge have been pumped out, the technician will clean the system thoroughly, including the pipes, tank, and any other components.

After cleaning, the technician may perform tests to ensure the system is functioning properly, such as measuring the levels of bacteria or checking the flow rate.

The technician may also perform any necessary maintenance tasks, such as replacing filters, checking pumps, or repairing any damaged components.

Finally, the technician will provide a report of the service, including any issues or recommendations for further maintenance or repairs.

These are a basic guide to the process and your specific Rewatec treatment plant will need servicing customised its build and operation, don’t worry there is nothing we have not seen or serviced over the years so our engineers are fully equipped and experienced to tackle all types of system.

If you would like more detail on the process for your type of Rewatec system please get in touch with our friendly office staff who will be more than happy to discuss this with you.

*These steps, although necessary, are performed by our tanker operatives and are chargeable separately from our engineers’ visit. you may already have had your tank emptied and cleaned prior to our visit.

Not necessarily time to panic and start worrying about expensive repairs just yet, there could be a simple explanation but in all scenarios best to give us a call and get one of our engineers to pop around and assess the situation.

here is a list of common problems and their (usual) reasons;

| Symptom | Cause/Action |

|---|---|

| Strong Odour |

Excess chemicals in the plant Excessive laundry use Drains inadequately venting Lack of aeration |

| Air blower stopped | Switched off at the mains isolator Power Failure |

| Air blower is running but no turbulence | Air pipe has been blocked or squashed or has a problem such as the hose is split Air blower diaphragm split |

| Poor final effluent | Check the air blower is operating and delivering air to the bio-zone |

| Bio-zone chamber has grey colour | Check there is good supply of air to the plant. (turbulent pattern in Bio-zone) |

| Bio-zone has greyish to black colour and an offensive odour | Excessive laundry use |

| Bio-zone has a very light brown colour and has few suspended solids. White suds. | Lightly loaded - Check that no surface water is entering the plant |

| Bio-zone is black in appearance | Plant is organically over-loaded Not enough air is getting to the bio-zone. |

| Grease balls in the bio-zone. | Too much grease in effluent. Excessive laundry use |

If you would like more help diagnosing your type of Rewatec system please get in touch with our friendly office staff who will be more than happy to discuss this with you.

Quite simply, we are the best!

We are always on hand, whether it be a routine visit, or an emergency call out to offer you the very best in Marsh Sewage Treatment Plant Maintenance. We pride ourselves on having a modern fleet of vehicles containing the highest tech equipment to ensure that we can provide you with the high levels of reliability and efficiency that we constantly achieve.

Our friendly and knowledgeable office team, are always available to discuss or advise on any of your requirements or simply to schedule in your Marsh Sewage Treatment Plant Maintenance at a convenient time and date that suits you.

On site, our team of dedicated, friendly and fully trained engineers will ensure that your emptying is carried out to the highest standard with minimal disruption. Our engineers are always willing and fully encouraged to spend time answering any questions you may have regarding your Sewage Treatment Plant Maintenance needs.

Annual servicing is essential to maintain optimal performance and comply with manufacturer guidelines. Regular maintenance helps prevent costly breakdowns and ensures the system operates efficiently.

Our comprehensive service includes inspecting and cleaning air diffusers, checking blower operation, assessing sludge levels, verifying effluent quality, and ensuring all mechanical and electrical components function correctly.

Indicators include unpleasant odors, slow drainage, gurgling sounds, or pooling water near the unit. These symptoms suggest it's time for a professional inspection.

Yes, Clearmasters is equipped to service various Rewatec (formerly Conder) models, ensuring comprehensive maintenance solutions tailored to your system's specifications.

Desludging is a separate process but can be coordinated with servicing. Regular removal of accumulated sludge is crucial for maintaining system efficiency and preventing blockages.

You can schedule a service by contacting Clearmasters directly through our website or by calling our customer service line. Our team will assist in arranging a convenient appointment.